Biomass Briquette Machine manufacturer Ludhiana

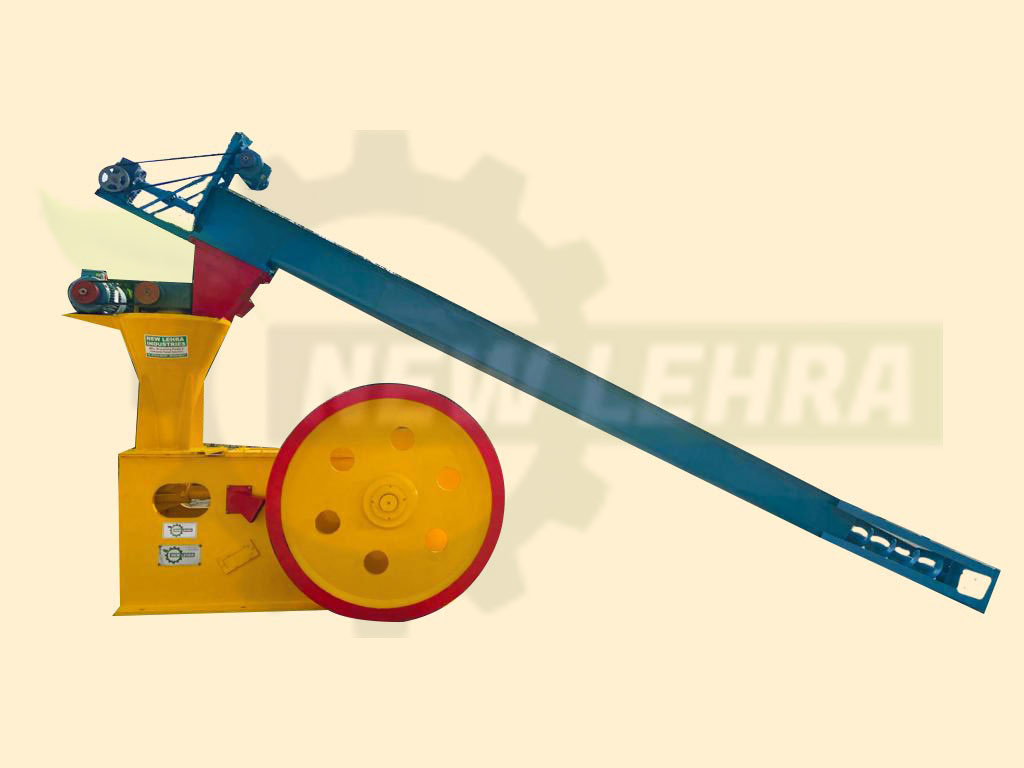

Biomass Briquetting Machines Ludhiana

Raw Materials for Briquetting : The raw material range our Biomass Briquetting Machine can handle includes but is not limited to the following:

Agricultural waste: Includes rice husks, mustard husks, paddy straw, groundnut shells, cotton stalks, sugarcane leaves and residues, coconut shells, arhar stalks, coir pith, coir dust, bamboo sticks and dust, coffee grounds, corn cobs, and similar materials.

Forest waste: Consists of sawdust, wood chips, tree branches, wood shavings, small twigs, veneer remnants, pine needles, and related byproducts.

Other waste: Encompasses press mud, municipal solid waste (MSW), paper scraps, and bagasse.

*For optimal results, ensure that the raw materials are granulated and maintain a moisture content of around 8-12%.

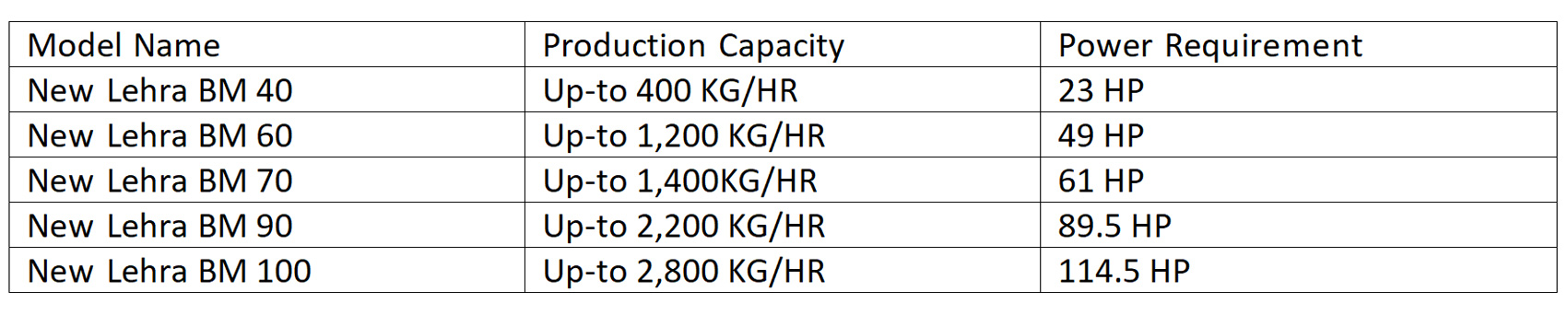

Briquette Size: Our machines are designed to accommodate various briquette sizes such as 40mm, 60mm, 70mm, 90mm, and 100mm, thus giving you the power to choose what best suits different needs and purposes.

Also known by : Briquetting Machine, White coal making machine, Bio coal machine, Jumbo 90 machine, Wood dust Briquette Machine, Rice husk Briquette machine, Paddy Straw Briquette Machine, Press mud Briquette Machine, Mustard Husk Briquette Machine, Bamboo dust Briquette Machine etc.

Why Buy Our Biomass Briquetting Machine in Ludhiana?

Binderless Technology: Our machines make quality briquettes with no need for additional adhesives. This helps in maintaining a cleaner production process and reduces your operation costs.

Environmental Impact: Our briquetting machines turn waste materials into useful energy, hence reducing dependence on fossil fuels and ensuring a lower carbon footprint, leaving a greener planet.

Waste utilization effectively: Our machinery effectively converts the waste into useful fuel. In this way, it solves the problem of waste management and extracts a new source of income out of wasted material.

Applications

Our Biomass Briquetting Machines find their applications across several industries and purposes:

Industrial Boilers: Heat and steam generation.

Residential Heating: An alternative source of heat for residences.

Power Generation: Biomass power plants.

Agricultural Application: Power machinery and tools.

Get Started with Green Energy

New Lehra joins green movement for sustainable future. Always feel free to contact us to learn more about our technology, get a quote, and schedule a demo. Together, we will make a difference in waste management and energy production.

FAQs

A briquette machine, also known as a briquetting machine, is a device that compresses a powdered material such as charcoal, sawdust, or biomass into a briquette. Briquettes are made of various materials and are used for different purposes such as fuel, cooking, and industrial processes.

The briquetting process involves compressing the material with high pressure and temperature, using a piston or a screw. The pressure and temperature cause the material to soften and bind together, forming a dense and solid briquette.

Briquette machines come in various types and sizes, ranging from small manual machines to large fully automated systems. They can be powered by electricity, diesel, or gasoline engines, or even by hydraulic systems.

Briquette machines are used in various industries such as agriculture, forestry, and manufacturing. They are used to produce briquettes for fuel, charcoal, and other applications. Briquettes are a sustainable and eco-friendly alternative to traditional fuels such as coal and wood, and can help reduce carbon emissions and deforestation.

Briquette machines are used to produce briquettes from various materials for a variety of purposes. Here are some common uses of briquette machines:

Fuel: Briquettes made from biomass such as wood, sawdust, and agricultural waste are used as fuel for heating and cooking in homes, restaurants, and industries.

Charcoal: Briquettes made from charcoal powder are used as a substitute for traditional charcoal in grilling and barbecuing.

Industrial processes: Briquettes made from industrial waste such as metal chips, dust, and shavings are used in manufacturing processes to reduce waste and save on raw material costs.

Animal feed: Briquettes made from animal waste such as poultry manure and cow dung can be used as a fertilizer and a source of protein for animal feed.

Recycling: Briquette machines are used to compress and recycle waste materials such as paper, cardboard, and plastic.

Overall, the use of briquette machines provides a sustainable and eco-friendly alternative to traditional fuels and materials, while also helping to reduce waste and save on costs.

There are several types of briquette machines, each with different designs and capabilities. Here are some of the most common types:

Mechanical briquette machine: This type of machine uses a mechanical crank or lever to compress the material. It is typically used for small-scale production and is manually operated.

Screw press briquette machine: This type of machine uses a screw to compress the material. The screw rotates inside a chamber, forcing the material through a die to form a briquette. Screw press machines are commonly used for large-scale production and can be fully automated.

Hydraulic briquette machine: This type of machine uses hydraulic pressure to compress the material. The material is fed into a chamber, where it is compressed by a hydraulic piston. Hydraulic machines can produce briquettes of high density and quality, and are suitable for large-scale production.

Piston press briquette machine: This type of machine uses a piston to compress the material. The piston is driven by a hydraulic system, which applies pressure to the material to form a briquette. Piston press machines are typically used for small to medium-scale production.

Roll press briquette machine: This type of machine uses two rollers to compress the material. The material is fed between the rollers and is compressed into a briquette. Roll press machines are commonly used for industrial-scale production and can produce briquettes of high density and quality.

Each type of briquette machine has its own advantages and disadvantages, and the choice of machine depends on factors such as the type of material, the desired output, and the available resources.