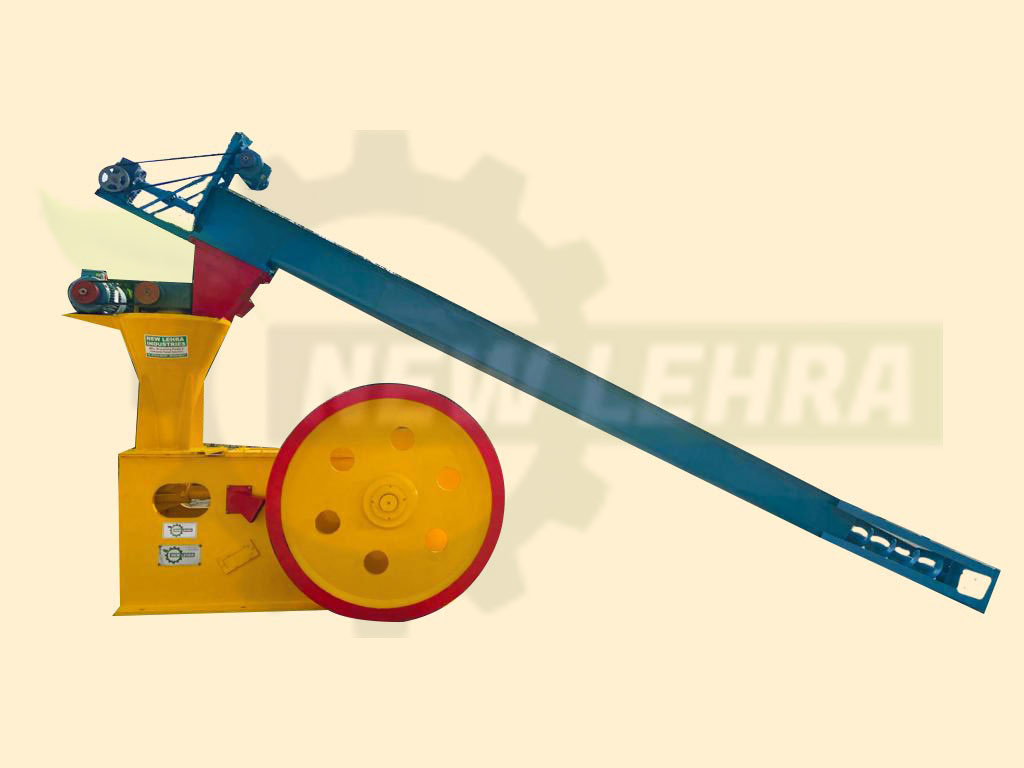

Biomass Briquetting Machines

Briquette Machine is used to make Briquette out of any agricultural and forest waste. Briquette are used in the replacement of fossil fuels which intern proves to be an environmental friendly product. This a Binder less technology. No adhesive or binder is used while producing Briquettes from our machines.

Raw materials: Raw materials which can be used to make Briquettes:

Agricultural waste: Rice husk, Mustard husk, Paddy straw, Groundnut shells, Cotton stalks, Sugarcane leaves and trash, Coconut shells, Arhar stalks, Coir pith, Coir dust, Bamboo sticks, Bamboo dust, Coffee waste, Corn cobs waste, Coffee waste etc.

Forest waste: Saw dust, Wood chips, Tree branches, Wood shavings, Tree twigs, Veneer waste, Pine needles etc.

Other waste: Press Mud, MSW, Paper waste, Bagasse.

*Input raw material has to be in granulated form with the moisture content between 8-12%

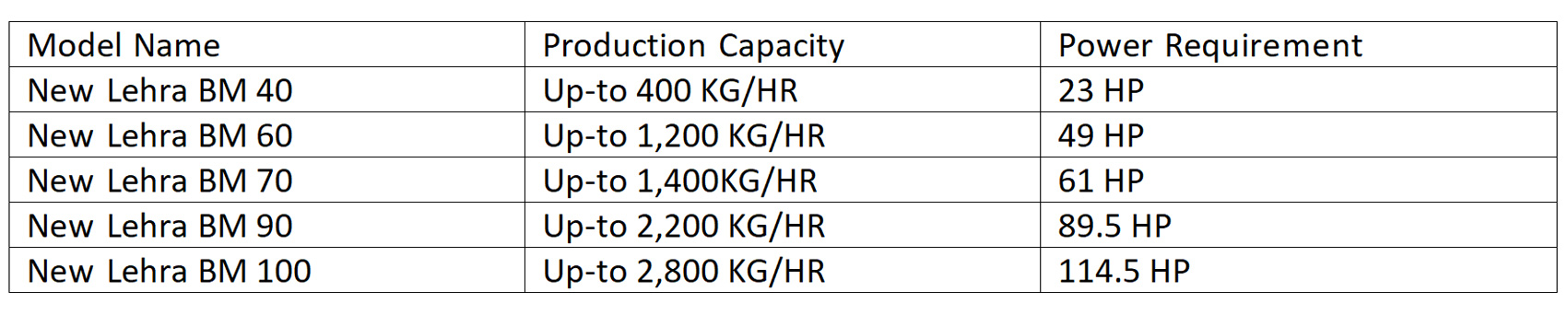

Briquette Size: 40mm/60mm/70mm/90mm/100mm

Also known by : Briquetting Machine, White coal making machine, Bio coal machine, Jumbo 90 machine, Wood dust Briquette Machine, Rice husk Briquette machine, Paddy Straw Briquette Machine, Press mud Briquette Machine, Mustard Husk Briquette Machine, Bamboo dust Briquette Machine etc.

FAQs

A briquette machine, also known as a briquetting machine, is a device that compresses a powdered material such as charcoal, sawdust, or biomass into a briquette. Briquettes are made of various materials and are used for different purposes such as fuel, cooking, and industrial processes.

The briquetting process involves compressing the material with high pressure and temperature, using a piston or a screw. The pressure and temperature cause the material to soften and bind together, forming a dense and solid briquette.

Briquette machines come in various types and sizes, ranging from small manual machines to large fully automated systems. They can be powered by electricity, diesel, or gasoline engines, or even by hydraulic systems.

Briquette machines are used in various industries such as agriculture, forestry, and manufacturing. They are used to produce briquettes for fuel, charcoal, and other applications. Briquettes are a sustainable and eco-friendly alternative to traditional fuels such as coal and wood, and can help reduce carbon emissions and deforestation.

Briquette machines are used to produce briquettes from various materials for a variety of purposes. Here are some common uses of briquette machines:

Fuel: Briquettes made from biomass such as wood, sawdust, and agricultural waste are used as fuel for heating and cooking in homes, restaurants, and industries.

Charcoal: Briquettes made from charcoal powder are used as a substitute for traditional charcoal in grilling and barbecuing.

Industrial processes: Briquettes made from industrial waste such as metal chips, dust, and shavings are used in manufacturing processes to reduce waste and save on raw material costs.

Animal feed: Briquettes made from animal waste such as poultry manure and cow dung can be used as a fertilizer and a source of protein for animal feed.

Recycling: Briquette machines are used to compress and recycle waste materials such as paper, cardboard, and plastic.

Overall, the use of briquette machines provides a sustainable and eco-friendly alternative to traditional fuels and materials, while also helping to reduce waste and save on costs.

Biomass Briquetting Machine India and Biomass Briquetting Machine South Africa are both home to several reputable biomass briquetting machine manufacturers.

A briquette machine compresses agricultural and biomass waste into solid fuel briquettes. These briquettes serve as an alternative to coal and firewood. The machine converts loose biomass into dense, uniform fuel blocks.

Yes, briquette making is profitable as it converts low-cost biomass waste into a valuable fuel product. Proper raw material sourcing and machine capacity are important in this regard to make operating margins attractive. Demand from industries makes it a sustainable business.

The briquettes business is profitable due to increasing demand for renewable and eco-friendly fuels. Industries prefer briquettes to reduce fuel costs and emissions. Profit depends on production scale as well as raw material availability. Logistics is yet another essential factor.

Briquettes are cleaner, renewable alternatives. They’re made from agricultural waste. On the other hand, carbonization produces charcoal. Briquettes offer consistent burning and lower emissions. Choice depends on the application and fuel requirement.

Common biomass materials include sawdust and rice husk. Also, there are groundnut shell bagasse. Other materials are mustard husk and crop residue. The best biomass is locally available with low moisture content. Proper size and dryness improve briquette quality.

Sawdust and agro-waste like rice husk, groundnut shell are widely used. Also, many prefer bagasse. The best raw material is one that is easily available year-round. Low moisture and good binding properties are important.

The number of briquettes per kg depends on the briquette diameter and length. On average, 1 kg may contain 6–12 briquettes. This varies based on compression and machine settings.

Burning time depends on charcoal quality and density. Also, a factor worth considering is the airflow. On average, 1 kg of good charcoal or briquettes can burn for several hours. Industrial use may consume fuel faster than domestic use.

There are several types of briquette machines, each with different designs and capabilities. Here are some of the most common types:

Mechanical briquette machine: This type of machine uses a mechanical crank or lever to compress the material. It is typically used for small-scale production and is manually operated.

Screw press briquette machine: This type of machine uses a screw to compress the material. The screw rotates inside a chamber, forcing the material through a die to form a briquette. Screw press machines are commonly used for large-scale production and can be fully automated.

Hydraulic briquette machine: This type of machine uses hydraulic pressure to compress the material. The material is fed into a chamber, where it is compressed by a hydraulic piston. Hydraulic machines can produce briquettes of high density and quality, and are suitable for large-scale production.

Piston press briquette machine: This type of machine uses a piston to compress the material. The piston is driven by a hydraulic system, which applies pressure to the material to form a briquette. Piston press machines are typically used for small to medium-scale production.

Roll press briquette machine: This type of machine uses two rollers to compress the material. The material is fed between the rollers and is compressed into a briquette. Roll press machines are commonly used for industrial-scale production and can produce briquettes of high density and quality.

Each type of briquette machine has its own advantages and disadvantages, and the choice of machine depends on factors such as the type of material, the desired output, and the available resources.

The purpose of briquette machines is to convert various materials into briquettes of different shapes and sizes for a variety of purposes.

Used briquette machine prices vary based on condition, capacity, and brand. They are generally available at a lower cost than new machines. It’s worth checking the performance and maintenance history beforehand. Used New Lehra briquette machines are available in the ₹2,00,000 – ₹4,50,000 range.

Cow dung briquettes are becoming popular as biomass fuel. Prices vary based on density and moisture content. Another deciding factor is location. Bulk pricing is commonly lower for industrial buyers. They typically sell around ₹8 – ₹15 per kg (₹8,000 – ₹15,000 per ton).

Charcoal prices per ton depend on quality, carbon content, and usage type. Industrial charcoal is different from domestic fuel in terms of cost. Market demand and location influence the final cost. Charcoal or charcoal briquettes generally cost around ₹4,000 – ₹8,000 per ton. Higher-grade or industrial briquettes can be priced higher.

Yes, cow dung briquette making can be profitable due to low raw material cost. It also supports waste management and renewable energy goals. Profit depends on scale, demand, and distribution.

The cow dung briquetting machine depends on capacity and design. Prices vary for small and industrial-scale machines. Investment selection should match production and raw material availability. It generally ranges from approximately ₹3,90,000 – ₹5,17,999 for mid-capacity commercial units. The price is for 20–30 HP screw-type machines.

Major biomass producers include agricultural economies with large crop residue availability. India, China, and the USA are among the leading biomass-producing regions. Biomass availability supports fuel briquette industries.

The best briquette machine manufacturer is one that offers durable machines. Also, it’s worth noting the consistent output and strong after-sales support. New Lehra provides reliable briquetting solutions for various biomass types. Machine selection depends on capacity and application.

Charcoal briquette machine prices in India vary by capacity and automation level. Small machines start from a few lakhs. Higher-capacity models cost more. Final pricing depends on output requirements. Prices for charcoal or coal briquette machines generally fall in the range of ₹3 lakh – ₹16 lakh+. Capacity and features are determining factors in this regard. Small or medium machines around ₹3 – ₹6 lakh. again higher-capacity industrial machines cost ₹10 – ₹16 lakh+.

A briquettes manufacturing plant’s cost depends on capacity and raw material handling. Also, a factor deciding the price is automation. Small setups require lower investment. Large plants need higher capital. Costs include machinery, installation, and utilities. Setting up a briquettes manufacturing plant typically ranges from around ₹25 lakh – ₹60 lakh for a small-scale 1–2 TPH unit. medium to larger plants can cost ₹1 crore – ₹3 crore+.