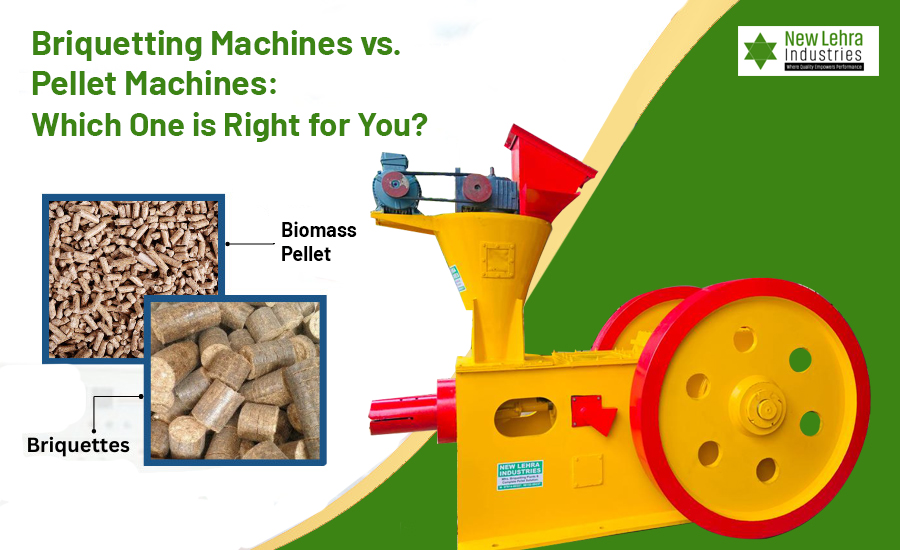

Both briquette and pellet machines are known for their ability to densify biomass for easier storage, transportation, and combustion. That being said, these machines prove impressive in terms of their ability to offer a sustainable alternative to fossil fuels and reduce waste. If you’re asking which would serve as a better option: a Briquetting Machine or a Pellet Machine, it’s worth noting that the choice depends on the desired application. In this regard, it’s known that the pellets are more efficient and possess higher energy density, while briquettes are more versatile in terms of shape and size.

Choosing between a briquetting machine and a pellet machine is completely dependent on your needs. Before making the final decision, note that briquettes are larger and suited for industrial heating and charcoal production. On the contrary, pellets are smaller and ideal for household heating and some industrial applications.

See their differences as well to make an informed decision.

The key difference between the two

Biomass pellet machines make biomass raw material powder into cylindrical sticks with a 2-12mm diameter. Their small volume makes it easier for biomass pellets to burn fully for homes or boilers. In addition, they find wide usage in terms of their ability to produce horse bedding and power.

Biomass briquette machines are widely used to make powdery biomass into large-diameter sticks. In this regard, note that the briquettes can be round, square, or hexagonal, according to the preferences of the customers. Usually, briquettes are widely used for BBQs, heating boilers, and electricity generation.

After considering the above-mentioned aspects, you can choose the proper machine for your biomass. Know your own requirements or market demand, whether or not you want to make biofuel for sale or for your own use, and based on that, you can make the purchase decision.

Understanding the aspects influencing the purchase decision

- Purpose

To make solid biofuel for heating or selling to people who need home-use cooking/heating fuel for the pellet stove, it’s worth investing in a pellet machine. To produce fuel for industrial use, for example, power generation or central boiler, it’s worth choosing a large biomass pellet machine with a ring die. The alternative option for industrial purposes is a mechanical stamping biomass briquette machine.

The screw-type biomass briquette machine also proves ideal for making BBQ fuel. This machine manufactures briquettes that are used directly but are also found to be used as charcoal briquettes to sell at a higher price!

- Raw material

When choosing a machine, consider your raw material. Material characteristics play a significant role when it comes to choosing the right machine for the purpose. Both the pellet machine and biomass briquette machine have the ability to produce fuel from sawdust, peanut shell, rice husk, wood, straw, stalk, etc., for processing alfalfa; what serves as a better choice is the pellet machine. When processing straws, you can rely on both machines, but comparing the two, it can be said that the pellet machine performs better. Choosing a pellet machine or a briquette machine depends on the purpose as well as the raw material, in addition to certain others.

- Budget

For a specific kind of raw material or a specific purpose, buy a pellet machine or a briquette machine. However, what else affects the decision is the price. When making the purchase decision, it is important to consider that different machines have different prices. Choose the machine that can meet your demand and falls under the set budget. The briquetting machine price in Ludhiana is affordable when you order from newlehra.com. The Pellet machine price in Ludhiana is quite reasonable as well.

- Place of use

Pellets are used in household fireplaces, industrial boilers, central heating boilers, power stations, or animal bedding. On the other hand, Briquettes are used as a solid fuel instead of firewood. What makes them advantageous is their lightweight composite, which makes them easy to store and transport.

There are various raw materials for the pellet mill and briquette machine, and biomass materials make up a huge proportion of the production. Pellet mills and briquette machines produce the same raw materials, but it is worth having an idea regarding the differences in their raw material types. Even after considering essential aspects, it can be concluded that the briquetting machine has more extensive adaptability. Usually, one will come across pellets with the same shapes and small rods, but that’s not the case with Briquettes. The latter are available in many types of shapes. Generally, briquettes are larger than pellets. Get a quote for briquetting and pellet machines in Ludhiana from newlehra.com that meet established national safety and performance standards.

A glance at the detailed comparison:

Briquettes:

- Raw Materials:

Briquettes focus on a wider range of materials, including metal scraps, agricultural and forest residues, and domestic garbage.

- Fuel Type:

Briquettes are widely used in large-scale heating applications, industrial boilers, and charcoal production.

- Machine Type:

Briquetting machines are available in several types- screw-type, hydraulic, or mechanical stamping.

- Advantages:

Briquettes are efficient for certain raw materials (like straw) and less expensive to operate and maintain.

- Disadvantages:

Briquettes are bulkier and less dense than pellets, and hence, they are less suitable for long-distance transport.

Pellets:

- Raw Materials:

Pellets primarily use biomass materials, including but not limited to wood, sawdust, and agricultural residues.

- Fuel Type:

Pellets are ideal for central heating boilers, domestic pellet stoves, and some industrial applications.

- Machine Type:

Pellet machines make use of the ring die or flat die technology.

- Advantages:

Pellets prove to be something that’s more compact and dense, making them easier to store and transport.

- Disadvantages:

Pelleting is more expensive to operate and maintain, and the preprocessing of raw materials is often more demanding.

Verdict – Which is better?

Green energy, especially in the form of biomass fuels, has been witnessing evergrowing popularity. Usually, several sectors look forward to cheaper, more efficient, and greener ways to produce energy. So it’s worth understanding that regardless of whether you choose the pellet-making machine or the briquette-making machine, you will find something as an efficient cost, cost-saving type of fuel that can be used personally or sold to make a profit.

Also, make sure you are considering aspects like your specific needs, raw materials, desired fuel type, and budget when making the decision of the briquette or pellet machine. Buy biomass briquetting and pellet machines in Punjab from trustworthy sellers, newlehra.com, that have earned a good reputation as a prominent manufacturer of renewable and non-conventional equipment.

Briquettes are a better choice when you are looking for large-scale industrial heating. On the other hand, pellets are more suitable, especially when you are looking for something for smaller, domestic applications.

Are you looking for Affordable pellet and briquetting machine suppliers? If yes, look no further than newlehra.com, which has been transforming the manufacturing landscape, driving efficiency, and promoting a sustainable future.