Briquette Cum Pellet Machine

Briquette cum Pellet Machine is used to make Briquette and Pellets out of any agricultural and forest waste. Briquettes and Pellets are used in the replacement of fossil fuels which intern proves to be an environmental friendly product. This a Binder less technology. No adhesive or binder is used while producing Briquettes from our machines.

Raw materials: Raw materials which can be used to make Briquettes:

Agricultural waste: Rice husk, Mustard husk, Paddy straw, Groundnut shells, Cotton stalks, Sugarcane leaves and trash, Coconut shells, Arhar stalks, Coir pith, Coir dust, Bamboo sticks, Bamboo dust, Coffee waste, Corn cobs waste, Coffee waste etc.

Forest waste: Saw dust, Wood chips, Tree branches, Wood shavings, Tree twigs, Veneer waste, Pine needles etc.

Other waste: Press Mud, MSW, Paper waste, Bagasse.

*Input raw material has to be granulated form with the moisture content between 8-12%

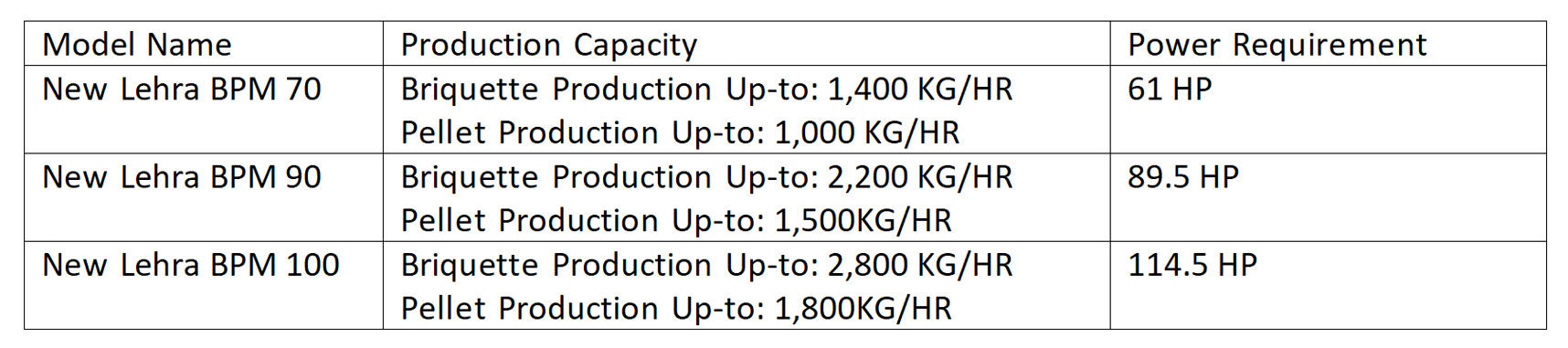

Briquette size: 70mm/90mm/100mm

Pellet Size: 8mm/10mm/12mm/20mm

FAQs

A briquette cum pellet machine is a type of machine that can produce both briquettes and pellets from various types of biomass or waste materials. This machine combines the advantages of both briquetting and pelleting, providing more flexibility and versatility in the production process.

Briquettes and pellets have similar uses as a source of fuel for heating and cooking, and can be made from materials such as wood chips, sawdust, agricultural waste, and other biomass materials. However, there are some differences between the two. Briquettes are typically larger and have a more uniform shape, while pellets are smaller and more compact.

The briquette cum pellet machine is designed to produce both types of fuel by using a combination of compression and extrusion. The material is fed into the machine, where it is compressed into briquettes or pellets depending on the type of die used. The machine can also be adjusted to produce briquettes or pellets of different sizes and shapes.

Overall, the briquette cum pellet machine is a versatile and efficient tool for producing biomass fuels, and can be used in various industries such as agriculture, forestry, and manufacturing. It provides a sustainable and eco-friendly alternative to traditional fuels, while also helping to reduce waste and save on costs.

There are several benefits of using a briquette cum pellet machine for producing biomass fuels, including:

Versatility: The machine can produce both briquettes and pellets from a variety of biomass or waste materials, providing more flexibility in the production process.

Efficiency: The machine uses compression and extrusion to produce briquettes and pellets, which results in high-density and uniform products. This makes them more efficient to transport and store.

Eco-friendly: Briquettes and pellets produced from biomass materials are renewable and carbon-neutral, making them a more sustainable and eco-friendly alternative to traditional fossil fuels.

Cost-effective: Using waste materials such as sawdust, agricultural waste, or forestry residues to produce briquettes and pellets is a cost-effective way to reduce waste and save on raw material costs.

Easy to use: Briquette cum pellet machines are easy to operate and can be adjusted to produce briquettes or pellets of various sizes and shapes.

Reduced emissions: Burning briquettes and pellets produces lower emissions than traditional fuels such as coal, which makes them a more environmentally friendly option.

Overall, using a briquette cum pellet machine provides several benefits for both the environment and the economy. It helps to reduce waste and save on costs, while also providing a sustainable and eco-friendly alternative to traditional fossil fuels.

There are several types of briquette cum pellet machines available in the market. Here are some of the common types:

Flat die pellet mill: This type of machine is designed to produce small scale pellets from biomass materials. It uses a flat die to compress and extrude the material to form pellets.

Ring die pellet mill: This is a more powerful and efficient machine that is capable of producing larger quantities of pellets. It uses a ring die and rollers to compress the material and form pellets.

Screw extruder briquette machine: This type of machine is designed to produce briquettes from biomass materials. It uses a screw extruder to compress the material and form briquettes of various shapes and sizes.

Piston press briquette machine: This is another type of machine that is used to produce briquettes from biomass materials. It uses a piston and a die to compress the material and form briquettes of various shapes and sizes.

Hydraulic press briquette machine: This is a more powerful and efficient machine that is used to produce high-density briquettes from biomass materials. It uses a hydraulic system to compress the material and form briquettes of various shapes and sizes.

Overall, the type of briquette cum pellet machine to use depends on the specific needs and requirements of the user, such as the scale of production, the type of biomass materials, and the desired output.