Agricultural waste material is a highly efficient, reasonable, and renewable source of biomass. But the low density and high volume of agriculturally produced biomass are the big obstacles in using the feedstock for the many processes comprising bio-energy production. Thus, biomass waste requires to be chopped with a hammer mill grinder to obtain high densification, uniformity, and bulk flow.

What are Hammer Mills and how do They Help in Size Reduction?

Size reduction is a necessary step for the densification and bio-energy conversion procedure to reduce transportation rates. Suitable size reduction lowers the volume of biomass, hikes the flow properties, increases the bulk density, changes particle size & shape, generates new surface area, and improves porosity.

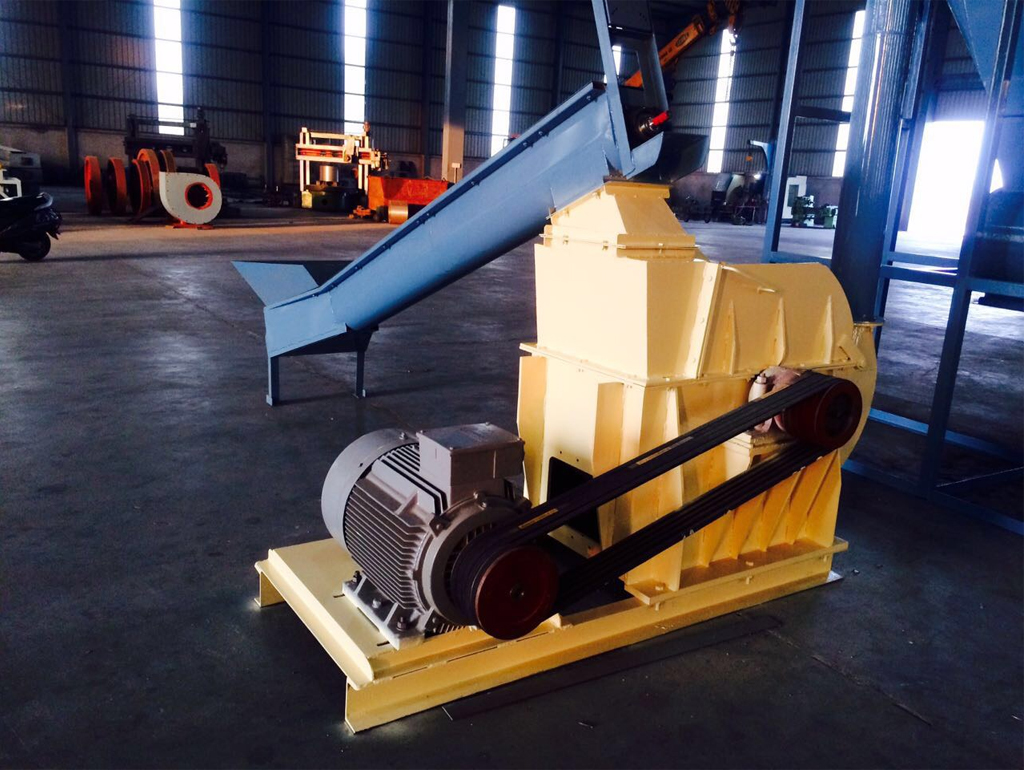

Hammer Mill grinders are the high-performance machines that finely grind an extensive range of biomass materials into 3 to 5 mm long so that they can be fed into the pellet mills or briquette machines. The feedstock comprises wood chips, small branches, straws, soybean stalks, hay, grass, twigs, coconut shells, hazelnut shells, black gram husk, walnut shells, cottonseed hulls, bamboo shavings, and different other natural wastes.

They have an easy design and rugged construction. The capacity of the machine to chop particles relies on its power. These versatile machines use huge velocity rotating shafts to transmit kinetic energy to the processed material. The hammers inside it beat the organic waste till it gets tiny enough to pass via a wire mesh. Also, for fine grinding less power is needed. The quality of the finished material relies on the rate of movement through the grinder machine and screen size.

Profitable For biomass pellet production

Production of high-density briquettes and pellets requires a quick and authentic grinding machine. The agricultural hammer grinder creates biomass pellets and briquettes tailored as per the requirements of the customers. Each completed product is homogeneous, high in quality, and has high energy efficiency. In fact, the effective utilization of the agro waste can provide new possibilities and prospects for the farmers.

Benefits of Biomass Pellets

- Ease of handling & storage because of its size

- Keeps the surrounding environment fresh & clean.

- Presence of fuel is better

- Low cost of storage as well as space.

- Affordable in comparison to coal as it uses wastes and residues.

- Automatic feeding in the boiler is feasible.

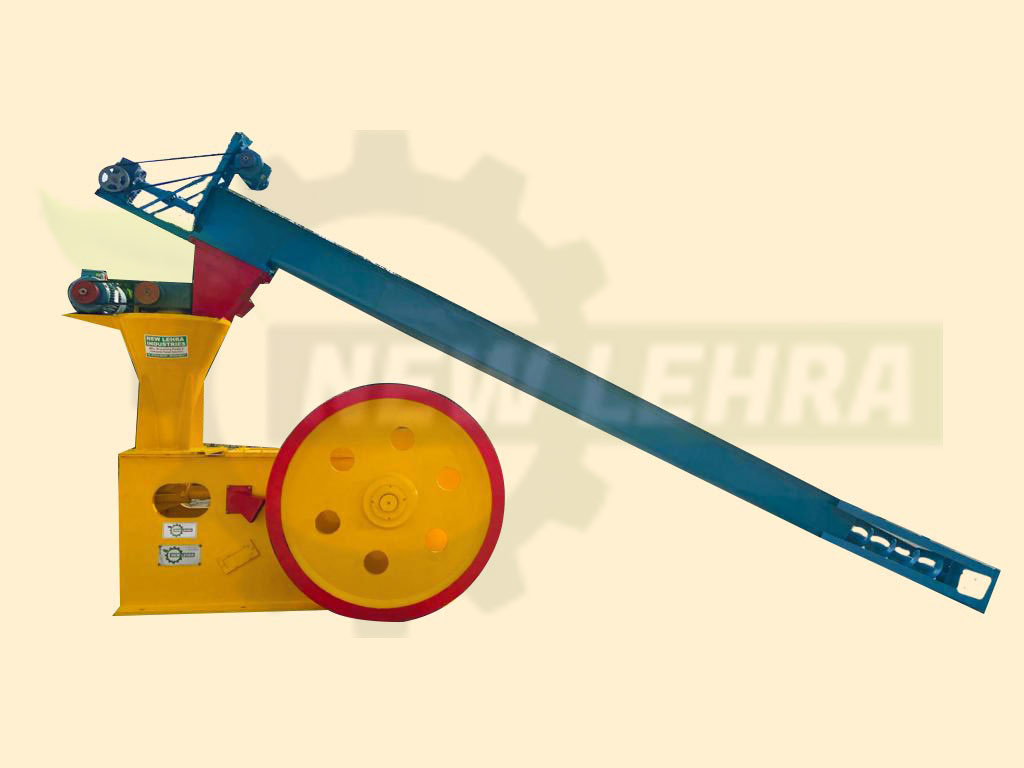

In-house hammer Mill grinder Manufacturing Unit

Newlehra is one of the best Hammer mill manufacturers in India which provides the toughest hammer grinders at an attractive & reasonable rate. We design the entire product with utmost precision using cut-edge tools, innovative machinery, and updated resources. Our products are highly efficient, durable, and made with first-class steel. We have highly trained experts who work on their toes to check every step during manufacturing.

The comprehensive range of models process biomass waste effectively and also cater the processing requirements of the customers instantly. We are one of the reliable Biomass Pellet Making Machine Importers, Exporters, and Suppliers who put a whole bag of tricks to supply top-grade machines which give value for money. Thus get in touch with our experts to clear your entire doubts. We are glad to help you. Connect with us over a call at the provided number or drop your necessities via email.