Award-Winning Industry [Green India Awards 2022]

We are pioneers in Bio-Mass Solutions for more than 30 years.

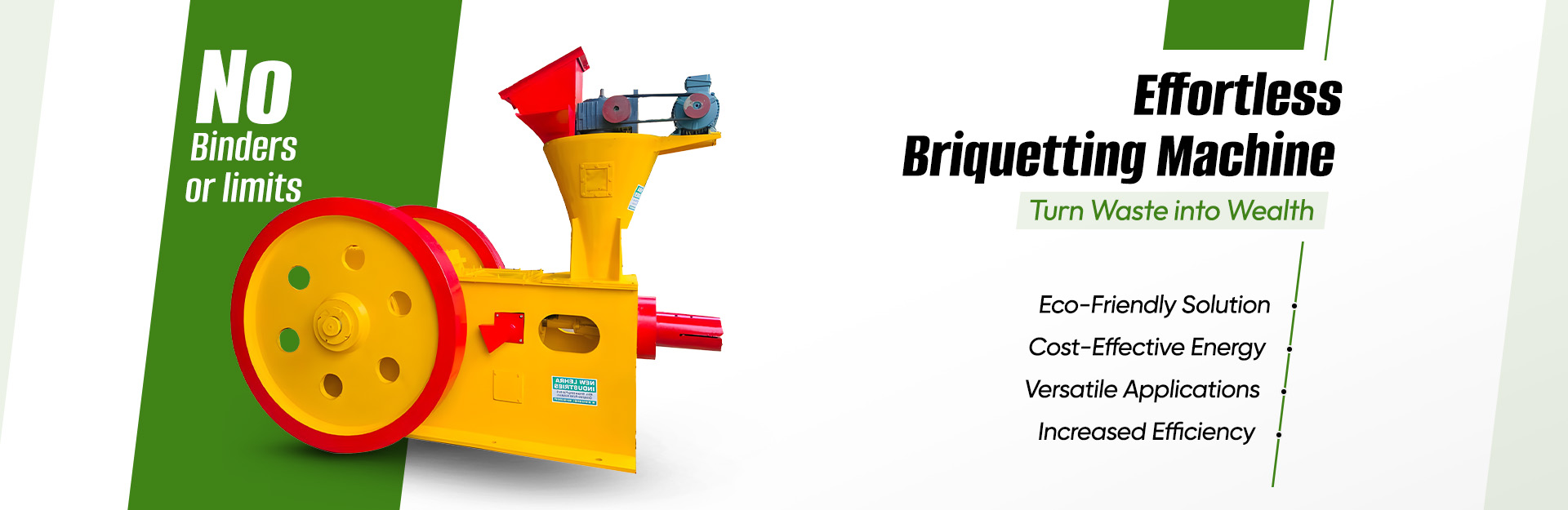

Biomass Briquetting Machine Manufacturer India

New Lehra Industries

Our Products

We are the Biomass Briquetting Machine manufacturer of renewable and non-conventional energy equipment i.e. Briqueting plants and machinery for converting agro-forestry waste into white coal; Biomass Briquetting Machines Systems & other energy equipment. For maintaining a consistent level of supremacy in our offered range, we ensure that all our products are developed only from premium grade factor inputs sourced from authentic vendors.

Biomass Briquetting Machine India come in various types and sizes, ranging from small manual machines to large automated ones. The process of making briquettes involves compressing the raw material under high pressure to form dense briquettes that can be burned for energy. The raw materials used for making briquettes in India include agricultural waste such as rice husk, straw, and sugarcane bagasse, and forestry waste such as sawdust and wood chips.

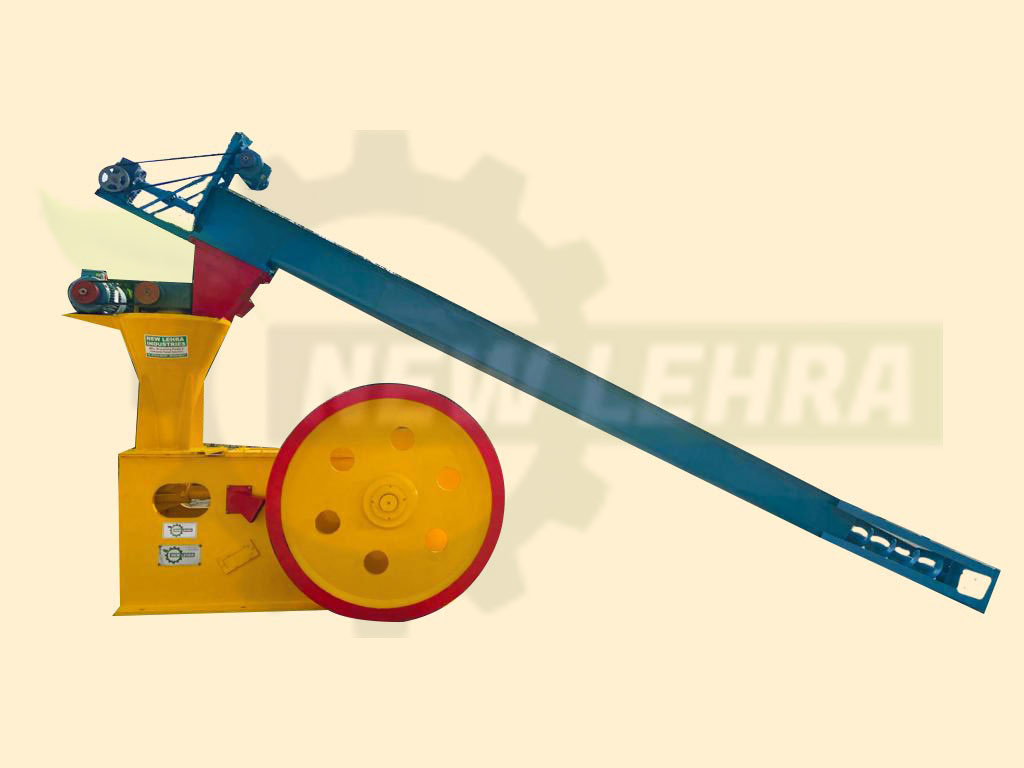

Briquette Machine is used to make Briquette out of any agricultural and forest waste.

Briquettes and Pellets are used in the replacement of fossil fuels.

Rotary Drum Dryer is designed to dry the material which contains high moisture up to 50%.

Flash dryer is used to decrease the moisture content of the granulated agricultural or forest waste.

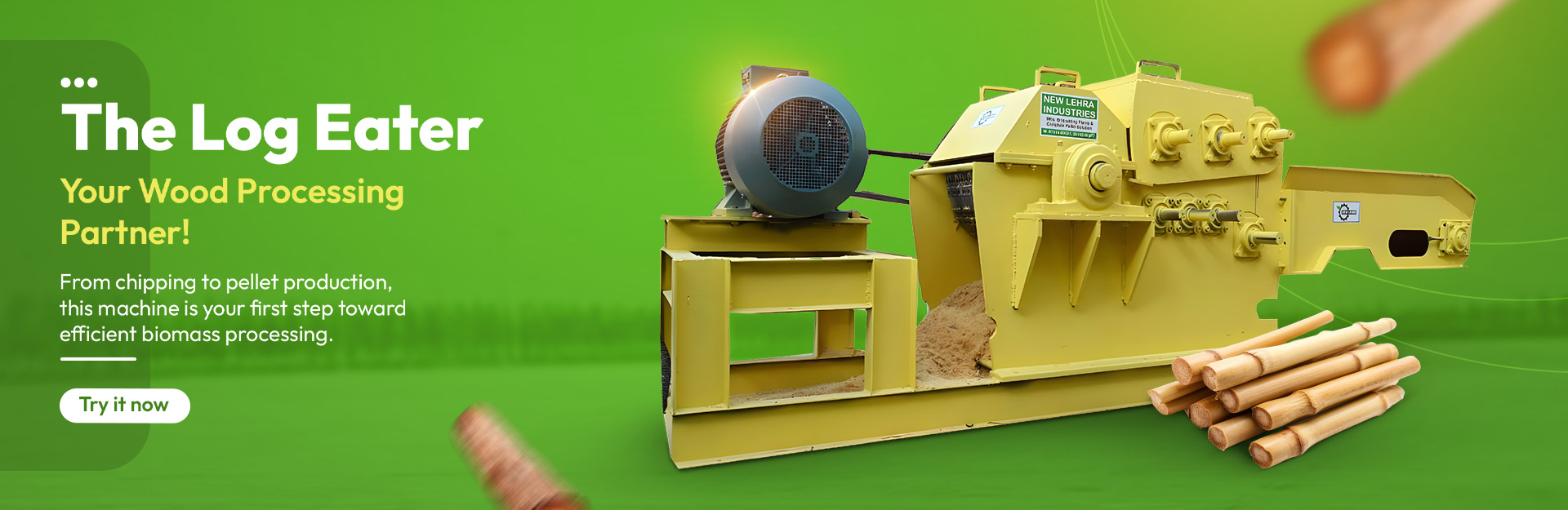

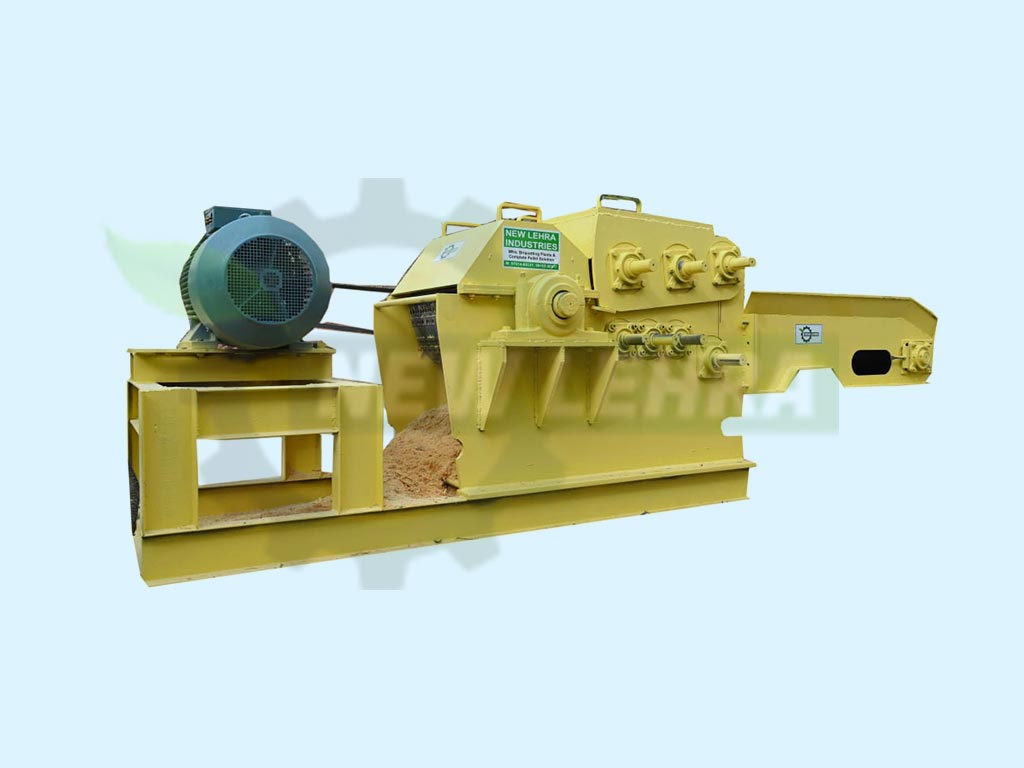

Log Eater is used to converting the Wood Logs into Sawdust/Powder without a hammer mill or grinding process.

Hammer Mill Grinder is used for the purpose of crushing the agriculture and forest waste into a granulated form

A Chipper grinder is used for chipping and cutting the agricultural and forest waste into smaller size.

A dust separator is used to dry the raw material having moisture up to 35%.

Our Story

Supplying The Best Bio-Mass Solutions Machinery Since 1989

With the pure dedication and commitment, Late Sr. Nahar Singh, the then Director, initiated the business looking forward to the ongoing environmental issues. By acknowledging the coming scarcity of the non-renewable energy resources, He made use of the then technology and built a machine which could produce Briquettes (white coal). He started the first plant in 1989 and have being growing thereafter.

Mr. Ghanaya Singh (S/O of Lt. Sr. Nahar Singh) left no stone unturned in taking the Company, NEW LEHRA INDUSTRIES to great heights. Owing to our advanced infrastructure, we offer superior quality products with in the promised time schedule.

Our infrastructure is compartmentalized into different units like production, quality testing, packaging, sales & marketing, etc. We have invested large amount of finance on the construction of our vast infrastructure that sprawl across a large area of land. This unit helps us store our bulk orders in a well-organized manner. Our team of experienced professionals enables us to offer superior quality products.

FAQ's

Briquetting equipment is used to compress loose and low-density materials into dense and consistent shapes. There are several types of briquetting equipment, including:

Briquette presses: Briquette presses come in different sizes and capacities, ranging from small manually operated presses to large fully automated systems. They are used to produce briquettes from a variety of materials, such as biomass, charcoal, and paper.

Briquette dryers: Briquette dryers are used to reduce the moisture content of the raw material before it is compressed into briquettes. This helps ensure that the briquettes have a consistent shape and burn more efficiently.

Hammer mills: Hammer mills are used to shred or crush the raw material into smaller pieces before it is compressed into briquettes. This can help improve the consistency and quality of the briquettes.

Biomass boilers: Biomass boilers are used to generate steam or hot water for heating or industrial processes using briquettes as a fuel source.

Briquette cutters: Briquette cutters are used to cut the briquettes to a specific size or shape for use in different applications.

The specific type of equipment used for briquetting will depend on the raw material being processed, the desired output, and the production capacity required.

There are several benefits of using a briquetting machine, including:

Waste reduction: Briquetting machines can help reduce waste by converting materials such as wood chips, sawdust, and agricultural waste into compact briquettes that can be easily transported and stored.

Energy savings: Briquettes produced by a briquetting machine can be used as a fuel source, reducing the need for traditional fuels such as coal, oil, and natural gas.

Improved handling: Briquettes are easy to handle and transport, making them ideal for use in industrial settings where large quantities of fuel are required.

Cost savings: Briquetting machines can help reduce waste disposal costs by converting waste materials into useful fuel sources. They can also help companies save money on energy costs by providing a more affordable fuel source.

Environmental benefits: Briquetting machines help reduce greenhouse gas emissions by reducing the need for traditional fuels. Additionally, the use of briquettes can help reduce deforestation by providing an alternative to wood-based fuels.

Overall, the use of a briquetting machine can provide significant benefits for companies looking to reduce waste, save money, and improve their environmental impact.

Briquettes are a compressed form of biomass or charcoal, typically used for fuel. There are several types of briquettes, including:

Biomass briquettes: These are made from agricultural waste such as rice husks, straw, and sugarcane bagasse, as well as forestry residues like sawdust and wood shavings.

Charcoal briquettes: These are made from charcoal powder, which is mixed with a binding agent such as starch or clay, and then compressed into shape. They are commonly used for grilling and barbecue.

Paper briquettes: These are made from recycled paper and other materials, and are typically used as a fuel for domestic heating.

Sawdust briquettes: These are made from sawdust and other wood residues, and are commonly used for heating and cooking.

Coconut shell briquettes: These are made from coconut shells, which are a by-product of the coconut industry. They are a sustainable alternative to charcoal, and are commonly used for cooking and heating.

The type of briquette you choose will depend on your specific needs and intended use.

The purpose of briquetting is to convert loose and low-density materials into dense and consistent shapes, typically for the purpose of fuel production. Briquetting provides several benefits:

Energy generation: Briquettes can be used as a fuel source for cooking, heating, and industrial processes. They burn more efficiently and produce less smoke and pollutants compared to traditional fuels like wood or coal.

Waste reduction: Briquetting can be used to convert waste materials into a useful fuel source. This can help reduce waste disposal costs and minimize the environmental impact of waste materials.

Resource conservation: Briquetting can help conserve natural resources by using renewable and sustainable materials, such as agricultural and forestry residues, to produce fuel.

Cost savings: Briquetting can provide cost savings by reducing the volume of waste materials and providing a cheaper and more efficient fuel source compared to traditional fuels.

Overall, the purpose of briquetting is to provide a sustainable and efficient fuel source that can help reduce waste, conserve resources, and save costs.

Our Blog

News & Updates

How New Lehra Industries meets the growing demand for reliable industrial products through advanced biomass solutions

The growing industrial landscape has been undergoing a significant transformation...

Read MoreTop 10 Raw Materials for Briquetting: Maximizing Local Agro-Waste

Industries and energy producers increasingly adopt renewable fuel solutions. In...

Read MoreWhat is a Rotary Drum Dryer? Why Choose a Rotary Drum Dryer over a Flash Dryer?

In modern industrial processing efficient drying systems play a critical...

Read MoreSend us Your Enquiries Here..

Our TESTIMONIALS

What People Say About Us